Extraction

We utilize cold ethanol extraction(-20c) to produce a high-quality CBD/CBG crude that retains an authentic cannabinoid and terpene profile to our farmer’s biomass.

We utilize cold ethanol extraction(-20c) to produce a high-quality CBD/CBG crude that retains an authentic cannabinoid and terpene profile to our farmer’s biomass.

We begin our process by chilling our ethanol to a minimum of -20c. With the unique polarity properties of Ethanol this ensures that we target our desired cannabinoids, flavonoids, and terpenes. While leaving behind a majority of the undesirable non-polar constituents such as the fats and waxes found in hemp/cannabis. For our primary extraction we have a Delta Separations CUP-15 centrifuge in our C1D2 booth. What this allows is for a single operator to process approximately 300lbs of biomass in an 8-hour shift.

What is collected from the extraction process via the CUP-15 is then brought into a -80c freezer for a minimum of 24 hours. This is where we begin out winterization process to remove any further undesirables that were captured through the initial point of extraction. Once the solution has reached an internal temperature of -80c it is then filtered through a 3-stage filtration housing skid where all of the solution in the last stage of the unit is passed through a 1-micron filter bag to separate the last of the fats and waxes from the material.

Once the undesirable compounds have fully been isolated from the material, we begin our solvent removal process. We utilize a Subzero-Scientific Falling Film Evaporator allowing us to recover up 30 gallons of Ethanol per hour. The advantages to the Falling Film Evaporator first being a significant increase in production output, but most importantly a very low residency time of your material being exposed to high temperatures, this allowing for your Crude to maintain as much as it’s original terpene profile as possible. Once the process of the Falling Film is completed, we are left with a high purity CBDa/CBGa crude with around 3-5% Ethanol remaining.

To increase the bioavailability of these compounds we need to decarboxylate the CBDa/CBGa. This is done through the process of heat and time. We take our material collected from the Falling Film Evaporator and pour it onto Pyrex pans where it will be placed in our Cascade Sciences Vacuum Ovens. Doing the decarboxylation process under vacuum allows us to fully decarboxylate the material at lower temperatures which in turn increases the retention of terpenes in the concentrate. This process is not only to increase the retention of terpenes and increase the bioavailability but as well, the material being under vacuum removes the last the residual Ethanol in the concentrate allowing a Residual-Solvent compliant CBD/CBG crude to be created.

We understand that high-quality, aesthetically, and sensory appealing concentrates are where the direction of the market is heading. In turn we have sourced a high end Wiped Film Evaporator from High Velocity Evaporators. We begin our process by removing the terpenes and low volatile compounds found in the crude as these under vacuum and distillation temperatures begin to degrade and often give distillates an unappealing odor/flavor. The low residency time of the CBD/CBG crude on this Wiped Film unit allow minimal conversions or degradations to occur during the distillation process compared to typical batch styled Short Path Distillation. What this creates is a high purity golden colored Distillate in ranges of 80-95% (based on source material %) with no odor allowing it to a great source concentrate for vape carts or white label products.

We focus on quality and purity. Batch repeatability is crucial in production and with varying source material the impact this can have on pre-established formulations and products can be disastrous. To create 99% pure compounds, we utilize USA-Labs glass Jacketed Reactors and super-saturate our CBD/CBG distillate into a non-polar solvent. Once fully dissolved we will slowly decrease the temperature of the solution with the external heater-chiller that is attached to the jacketed glass reactor so we can begin to precipitate out the target cannabinoid from the remaining constituents of the source material. This process can take anywhere from 3-4 hours to 1-2 days depending on the purity of the starting material. Once the target compound is full precipitated out from the solution it is filtered into a stainless-steel Buchner-style funnel with a 0.2-micron filter under vacuum to remove any of the remaining non-polar solvent and minor cannabinoids from the CBD/CBG Isolate. If any discoloration is observed, we utilize recrystallization methods in the reactor to increase the purity until the desired product/purity is achieved. This CBD/CBG isolate from the Buchner is then placed into Pyrex Trays to begin the residual solvent process removal in the Cascade Science Vacuum Ovens. After 24 hours under vacuum, we are left with an isolate that is now free of any residual solvents and within the range of 98-99% purity and will be placed into a grain mill to produce a homogenous white powder fantastic for consistent batch formulations or consumption.

Available beginning in 2024!

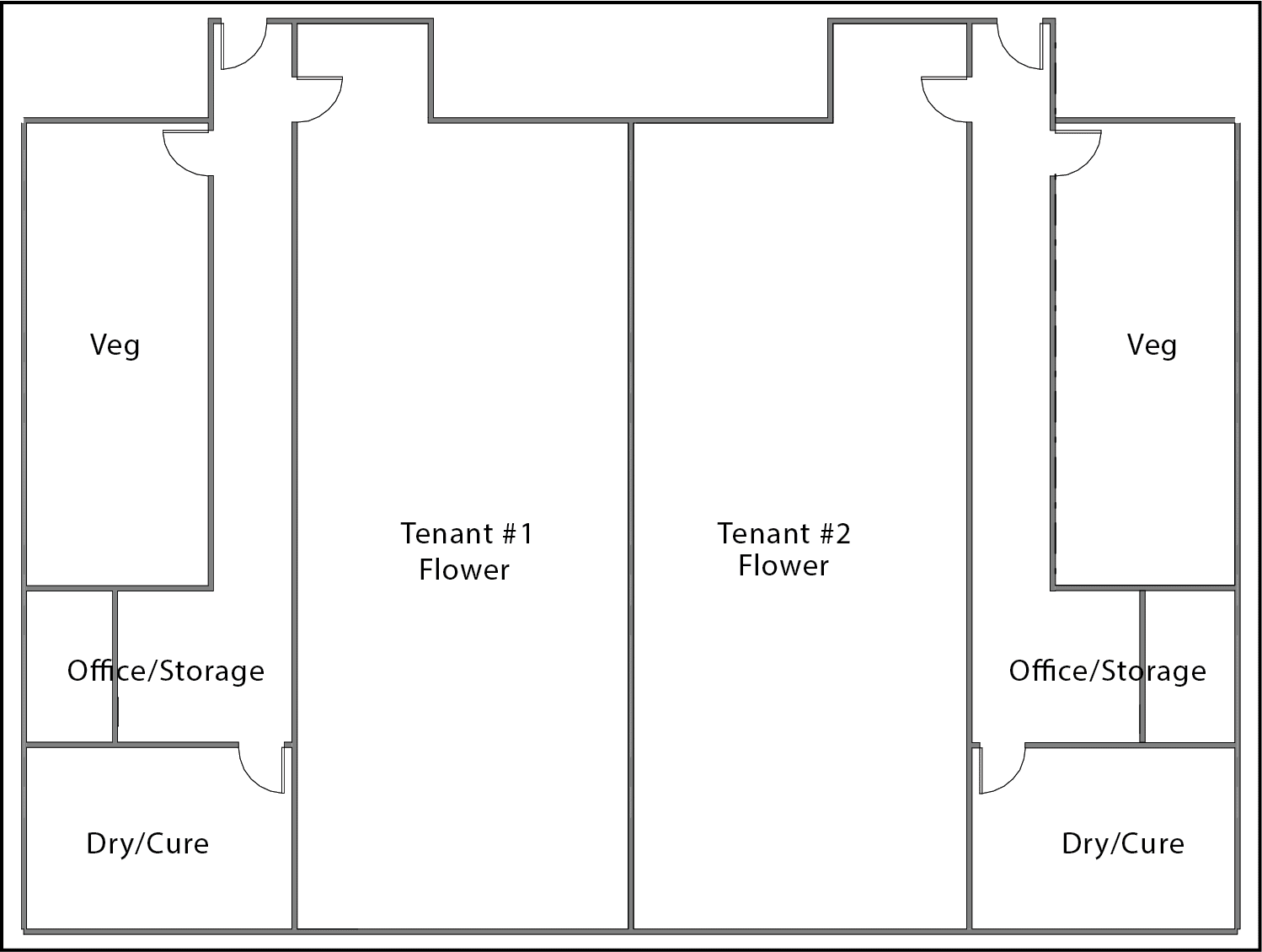

Satori VT will be providing ‘plug and grow’ suites, featuring top of the line HVAC, lights, racking, and irrigation. We’re excited to establish a collective where growers and companies can collaborate, innovate, and conduct their business in a fully compliant and environmentally sustainable facility.

Suites will range ranging from 2,000-to 2,400 sq. ft. to sublease. Each space will provide at least 1,000 sq. ft. of flower space and 1,400 sq. ft. of room for cultivation, drying and other activities.

Copyright © 2024 Satori

Site by CannaPlanners

Are you over 21 years of age?

You are not old enough to view this website.